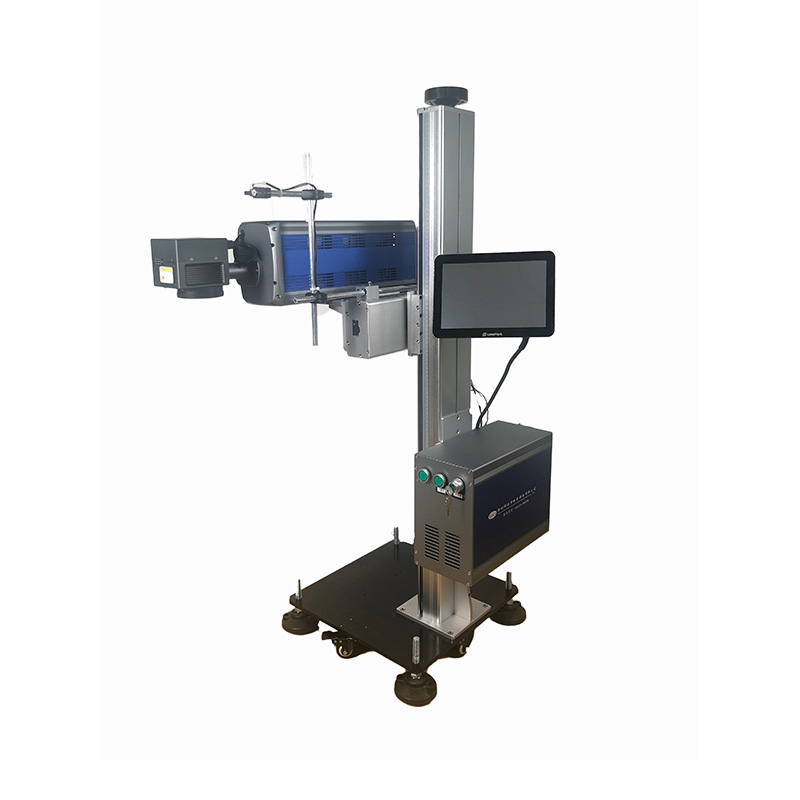

Ibhodlela elizenzakalelayo/ Umshini Wokufaka Amakhodi we-Laser

Incazelo

Uhlelo lokulawula ikhompuyutha luhlanganisa ikhompuyutha kanye nekhadi le-galvanometer yedijithali, futhi ingxenye yesistimu yokukhanya yokushayela ikhipha i-laser eshaya ngamandla ngokuya ngesenzo sepharamitha esisethwe isofthiwe yokulawula ukumaka, ngaleyo ndlela ibhala ngokuqondile okuqukethwe okufanele kumakwe ebusweni bento ecutshunguliwe. .

Isistimu yokulawula i-interface yesiNgisi egcwele, ehambisana ne-AUTOCAD, i-CORELDRAW, i-PHOTOSHOP namanye amafayela okukhipha isofthiwe, ingaba ikhodi yebha, ikhodi ye-QR, umbhalo wesithombe, njll., isekela i-PLT, i-PCX, i-DXF, i-BMP, i-AI namanye amafomethi wefayela, Ukusebenzisa ngokuqondile I-SHX ne-TTF amafonti, ungakwazi ukufaka ikhodi ngokuzenzakalelayo futhi uphrinte izinombolo ze-serial, izinombolo ze-batch, izinsuku, nokuningi.

I-adapting materials nezimboni:

Izipho zobuciko, ifenisha, izingubo zesikhumba, izimpawu zokukhangisa, ukwenza amamodeli, ukupakishwa kokudla, izingxenye ze-elekthronikhi, ukupakishwa kwemithi, amapuleti okuphrinta, ama-nameplate egobolondo, njll.

Izinto ezifanele ngokuyinhloko izinto ezingezona ezensimbi ezifana ne-bamboo nemikhiqizo yokhuni, iphepha, isikhumba sendwangu, i-plexiglass, i-epoxy resin, i-acrylic, i-polyester resin.

Izici

| Isici | |

| Umshini wokuqopha we-laser | Umshini wokufaka amakhodi we-laser |

| Iskena i-galvanometer | SCANLAB |

| Ilensi yokugxila | I-HMKS |

| Isistimu yendlela ye-Optical | Okujwayelekile |

| Isofthiwe | Ikhadi lokulawula isofthiwe yomshini wokumaka |

| Isixhumi esibonakalayo somsebenzi | Indawo yokusebenza *1 (ifomethi yokuphakamisa encane) |

| Ikhompyutha | Ikhompyutha Yokulawula Izimboni |

| Indawo yokumaka | 30W-- |

| Ubukhulu (L* W *H) | 78cm*50cm*136cm |

| Isisindo (NW) | 78KG |

| Ukuthutha okubandakanya konke, ukuqinisekiswa kwekhwalithi iminyaka emibili, ukufakwa nokuqeqeshwa kokuthunywa | |

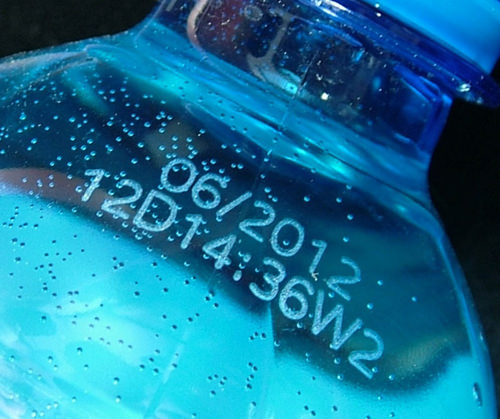

Umphumela Womkhiqizo

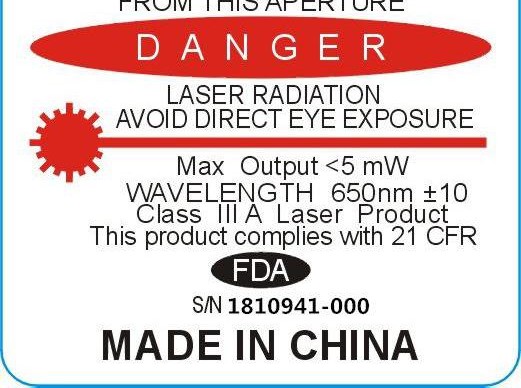

Idatha

| Cha. | Into | Phawula |

| 1 | laser wave ubude | 10.6 um |

| 2 | Amandla we-laser amaphakathi | 30W |

| 3 | Imvamisa yokuguquguquka | 20-120KHZ |

| 4 | Ukujula kokumaka | <0.2mm |

| 5 | Isivinini esikhulu sokumaka | 8000mm/s |

| 6 | Ububanzi bomugqa obuncane | 0.005mm |

| 7 | Amandla aphelele | 500W |

| 8 | Isivinini sokumaka | 800 izinhlamvu/s |

| 9 | Ukuphindaphinda kwe-Galvanometer | ± 0.05mm |

| 10 | indlela yokupholisa | Ukupholisa umoya ngabalandeli |

| 11 | Ikhwalithi ye-Beam | M2<1.3 |

| 12 | Impilo ye-laser | Amahora angu-10000(Ngedatha yokuhlola yobungcweti) |

| 13 | Ubuncane bezinhlamvu | 0.1mm |

Kulawo makhasimende aphesheya, inkampani yethu izosakaza amavidiyo bukhoma ukuze inikeze ukuqeqeshwa Kobuchwepheshe kuze kube yilapho umqhubi esefinyelele ukusetshenziswa okuyisisekelo okujwayelekile kwesisetshenziswa.

Okuqukethwe okuyinhloko kokuqeqeshwa kungokulandelayo:

① Ukuqeqeshwa kokuthi Isetshenziswa kanjani isofthiwe evamile yokudweba;

② Ukuqeqeshwa ekusebenziseni isofthiwe yokulawula ukumaka;

③ Ukuqeqeshwa Ekushintsheni izinqubo zokusebenza komshini;

④ Okushiwo iphaneli kanye nemingcele yokulawula isofthiwe, ukuqeqeshwa kohlu lokukhetha ipharamitha;

⑤ Ukuhlanza okuyisisekelo nokugcinwa komshini.

Ukugcinwa Kwezisetshenziswa

● Izisetshenziswa azinawaranti izinyanga ezingama-24 futhi zigcinwa impilo yonke.

● Ukubonisana kwamahhala kwezobuchwepheshe, ukuthuthukiswa kwesofthiwe nezinye izinsiza.

● Uma iwaranti yesisetshenziswa siphelelwa yisikhathi, isevisi yokulungisa izohlinzekwa impilo yonke, futhi izindleko zizokhokhiswa kuphela izesekeli.

● I-Hardware kanye nokusekelwa kwesofthiwe okubanzi kuyatholakala ngemva kokuphelelwa yisikhathi sewaranti.

Ingxenye Yabathengi