Umshini Wokugcwalisa Uwoyela Wesisindo Ozenzakalelayo

Incazelo

Incazelo

Ukugcwaliswa kwemikhiqizo kawoyela, okuhlanganisa uwoyela odliwayo kanye nowoyela wezimboni.Uwoyela odliwayo uyimboni eyinsika yomnotho wezwe, ungenye yezidlo ezisemqoka ekuphileni kwethu kwansuku zonke, njengamafutha e-peanut, amafutha esundu, amafutha ahlanganisiwe nokunye.Uwoyela wezimboni ikakhulukazi uwoyela wokugcoba, ngezinga eliphakeme lokuzenzakalelayo kwezimboni namuhla, zonke izinhlobo zemishini eyimishini ayikwazi ukusebenza ngaphandle kokugcoba, ukusetshenziswa okubanzi kakhulu.

Ukugcwaliswa kwemikhiqizo yamafutha kudinga ukunemba okuphezulu kokugcwalisa kanye nezimo zokuhlanzeka, okulula ukunamathela ebusweni bezingxenye futhi kubangele ukudonsa.Ukuze uxazulule lezi zinkinga, umshini wokugcwalisa uwoyela we-GEM awuqinisekisi kuphela izidingo zokugcwalisa, kodwa futhi ulungiselela izinkinga zokuvuza kalula.

Ngenxa ye-viscosity ephezulu yemikhiqizo kawoyela, ukusetshenziswa kwama-valve emishini evamile kuzodala ukuvinjelwa kwepayipi elibuyayo, ngakho-ke umshini wokugcwalisa uwoyela uvame ukusebenzisa indlela yokugcwalisa inani le-plunger.Umgomo we-plunger quantitative filling method ukuthi izinto eziku-cylinder yokulinganisa, isilinda sokugcwalisa, ibhodlela lokugcwalisa iziqukathi ezintathu zihlala zishintsha, zigeleza.Umzimba we-valve ulingana ne-valve enezinhlangothi ezintathu.Lapho i-valve ivaliwe, isilinda nesilinda kuxhunyiwe, futhi impahla imuncwa ku-cylinder ngepiston.Ukushaywa kwepiston kunquma umthamo wento emuncwayo, ngaleyo ndlela inquma umthamo wento egcwaliswayo.Lapho i-valve ivulwa, isilinda nebhodlela kuxhunyiwe, futhi izinto ezifakwe ku-cylinder zicindezelwa ebhodleleni ukuze kuqedelwe inqubo yokugcwalisa inani.Njengoba umthamo wokugcwalisa ungashintshwa ngokulungisa ukushaywa kwe-piston, kulula ukugcwalisa amabhodlela amakhono ahlukene.Ngaphezu kwalokho, ingxenye elawula i-piston ingashintshwa yi-servo drive, eyenza ukugcwaliswa kunembe kakhudlwana futhi umthamo ube lula.

Ngaphandle kokugcwalisa i-plunger, imishini eminingi yokugcwalisa uwoyela isebenzisa ubuchwepheshe bokugcwalisa isisindo.Ngemuva kokuthi isisindo esingenalutho sesitsha sinqunywa, i-valve yokugcwalisa ivuliwe lapho ibhodlela litholwa.Ngesikhathi sokugcwalisa, inzwa yokukala ithola inani lomkhiqizo ojovwe.Uma isisindo esidingekayo sifinyelelwe, i-valve ivala ngokushesha.Ngemuva kwesikhashana sokuphumula, phinda uhlole isisindo.Ngaphambi nje kokufinyelela isondo lebhodlela, i-valve iyaphakanyiswa futhi ukuze kuqinisekiswe ukuthi ibhodlela lishiya umshini uhlanzekile.Le ndlela yokugcwalisa ingenziwa ngokwezifiso ngomsebenzi we-CIP othomathikhi, ukuhlanza inkomishi yenkohliso ifakwe ngokuzenzakalelayo, i-CIP ayidingi ukusebenza okwenziwa ngesandla.

Izici zesakhiwo sobuchwepheshe

1. Ukugcwalisa okuvamile kusetshenziswa ukugcwaliswa kwe-plunger quantitative, ukunemba kokugcwalisa kuphezulu, kulula ukukushintsha.I-valve yokugcwalisa i-elekthronikhi enesisindo/i-electromagnetic flowmeter isetshenziselwa imikhiqizo enezidingo eziphezulu zomthamo.Kungakhathaliseki ukuthi hlobo luni lwe-valve yokugcwalisa ingavimbela ngempumelelo ukuvuza kwe-valve orifice.

I-2. Isistimu yokulawula ye-Siemens yamukelwa, inekhono lokulawula okuzenzakalelayo eliphezulu, zonke izingxenye zomsebenzi zisebenza ngokuzenzakalelayo ngokugcwele, akukho ukusebenza okudingekayo ngemva kokuqala (isibonelo: isivinini sokugcwalisa silandela isivinini somugqa wonke, ukutholwa kwezinga le-liquid, ukulawulwa kokuphuza uketshezi. , isistimu yokugcoba, isistimu yokudlulisa ikepisi yebhodlela)

3. Ukudluliswa komshini kusebenzisa ukwakheka kwe-modular, ukuguqulwa kwemvamisa ukulawulwa kwesivinini esingenasinyathelo, ukulawulwa okubanzi kwejubane.Idrayivu ifakwe i-othomathikhi yomshini wokugcoba amafutha, ongahlinzeka ngamafutha endaweni ngayinye yokugcoba ngokwesidingo sesikhathi kanye nenani, ngokugcotshwa okwanele, ukusebenza kahle okuphezulu, umsindo ophansi nempilo ende yesevisi.

4. Ukuphakama kwempahla kusilinda sokugcwalisa kutholwa yi-probe ye-elekthronikhi, futhi isilawuli se-PLC esivaliwe se-PID siqinisekisa izinga le-liquid elizinzile nokugcwalisa okuthembekile.

5. Ngokwezidingo zemikhiqizo ehlukene, indlela yokugcwalisa kanye nohlobo lokubeka uphawu lungafaniswa ngokuthanda kwakhe.Izindlela ezihlukene zokuvala ziyatholakala (isb., indlala yepulasitiki, isivalo sentambo yepulasitiki, njll.)

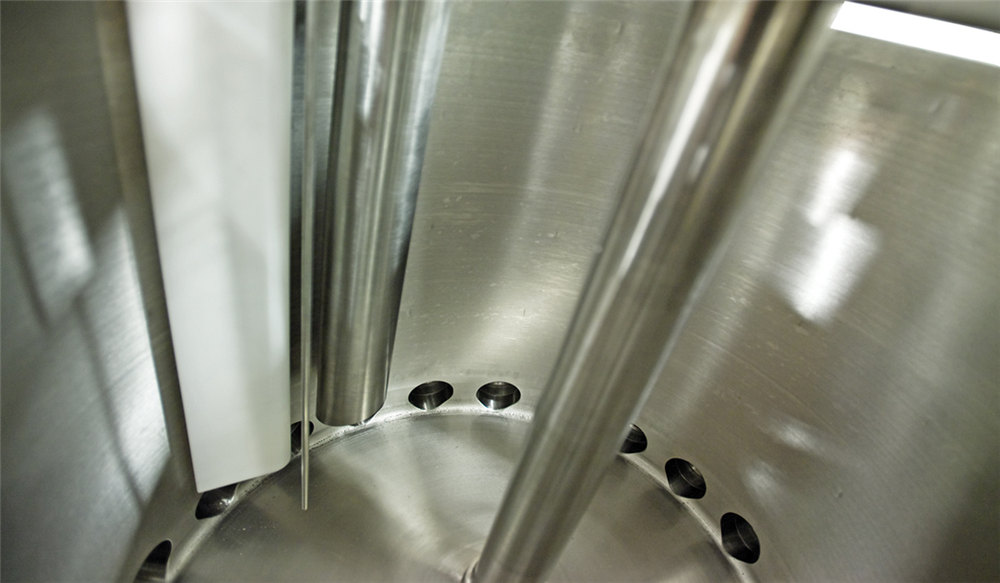

6. Isiteshi sezinto ezibonakalayo singahlanzwa i-CIP ngokuphelele, futhi ibhentshi lomsebenzi kanye nengxenye yokuxhumana yebhodlela ingagezwa ngokuqondile, ehlangabezana nezidingo zenhlanzeko zokugcwalisa;Ingasetshenziswa ngokuvumelana nesidingo setafula lokutsheka ohlangothini olulodwa;Izinkomishi mbumbulu ze-CIP ezizenzakalelayo nazo ziyatholakala.

7. Akukho ukuthintana phakathi kwebhodlela kanye ne-valve yokugcwalisa ngesikhathi sokugcwalisa ukugwema ukungcoliswa okuphambene.

Isakhiwo

Ipharamitha

| Cha. | Uchungechunge lwamamodeli | Material Viscosity range CPS | amandla | Ifakwe umthombo womoya | Ifakwe umthombo wamandla | Idlulisela ubude bomugqa

| efanelekayo uhlobo ibhodlela uhla |

| 01 | JH-OF-6 | 0-200 | 3kw | 5-6 ibha | 380V | 1000±50mm | Kwenziwe ngokwezifiso ngokwezidingo zekhasimende

|

| 02 | JH-OF-8 | 0-200 | 3kw | 5-6 ibha | 380V | 1000±50mm | |

| 03 | JH-OF-10 | 0-200 | 3.5KW | 5-6 ibha | 380V | 1000±50mm | |

| 04 | JH-OF-12 | 0-200 | 3.5KW | 5-6 ibha | 380V | 1000±50mm | |

| 05 | JH-OF-14 | 0-200 | 4.5kw | 5-6 ibha | 380V | 1000±50mm | |

| 06 | JH-OF-16 | 0-200 | 4.5kw | 5-6 ibha | 380V | 1000±50mm | |

| 07 | JH-OF-20 | 0-200 | 5kw | 5-6 ibha | 380V | 1000±50mm |