Umshini Wokugcwalisa Ithini Elizungezayo

Ividiyo

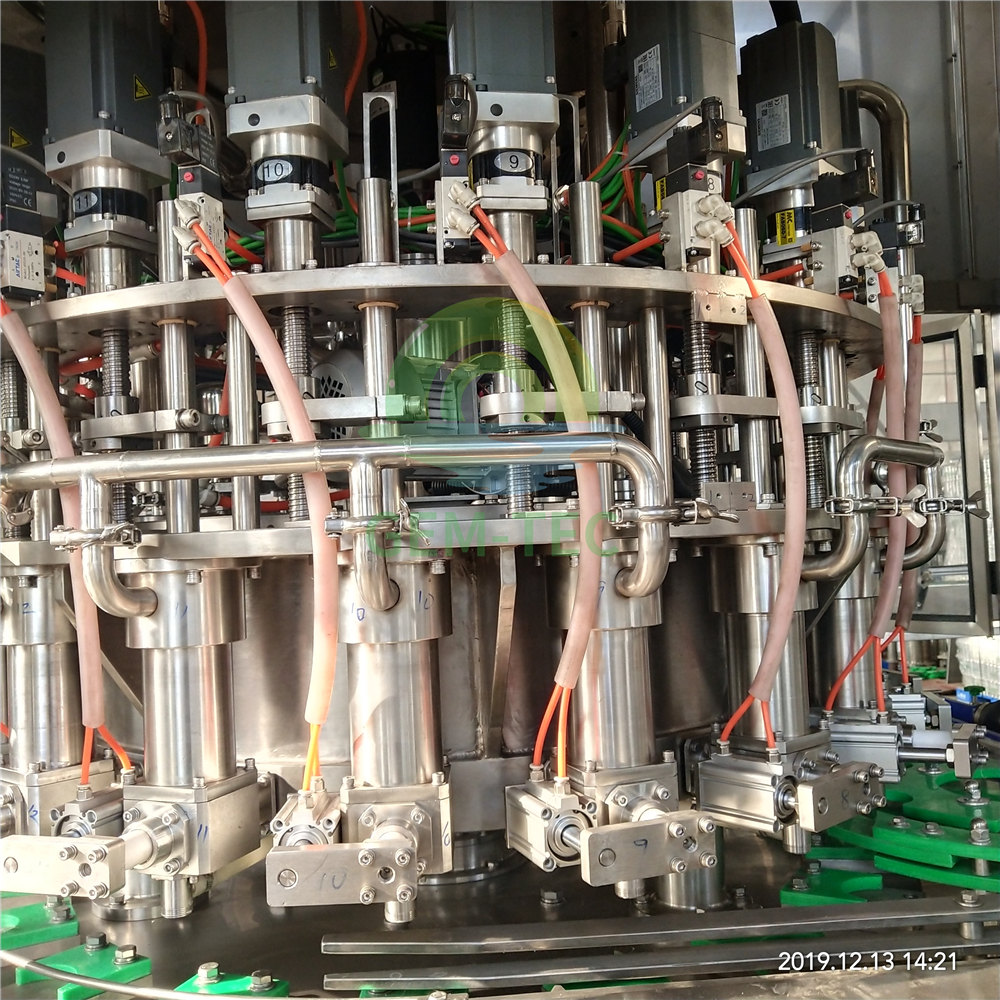

Incazelo

Amathini anesisindo sawo esilula, usayizi omncane, ukuphuka kalula, ukuthwala kalula nezinye izinzuzo, athandwa iningi lamaqembu abathengi.Ngesikhathi esifanayo, yenziwe ngezinto zensimbi, ngakho-ke inokuvikelwa okuhle ekukhanyeni.Ngokuphambene, amabhodlela engilazi anomsebenzi ongemuhle wokulwa nokukhanya.Uma amabhodlela engilazi eziphuzo noma ubhiya egcinwa, kudingeka abekwe endaweni epholile ukuze agweme ukukhanya kwelanga, ngaphandle kwalokho, impilo yeshalofu izothinteka.Lezi zici zenza amathini abe ngaphezu ngokuphelele kwamabhodlela engilazi kwezinye izindawo zokupakisha.

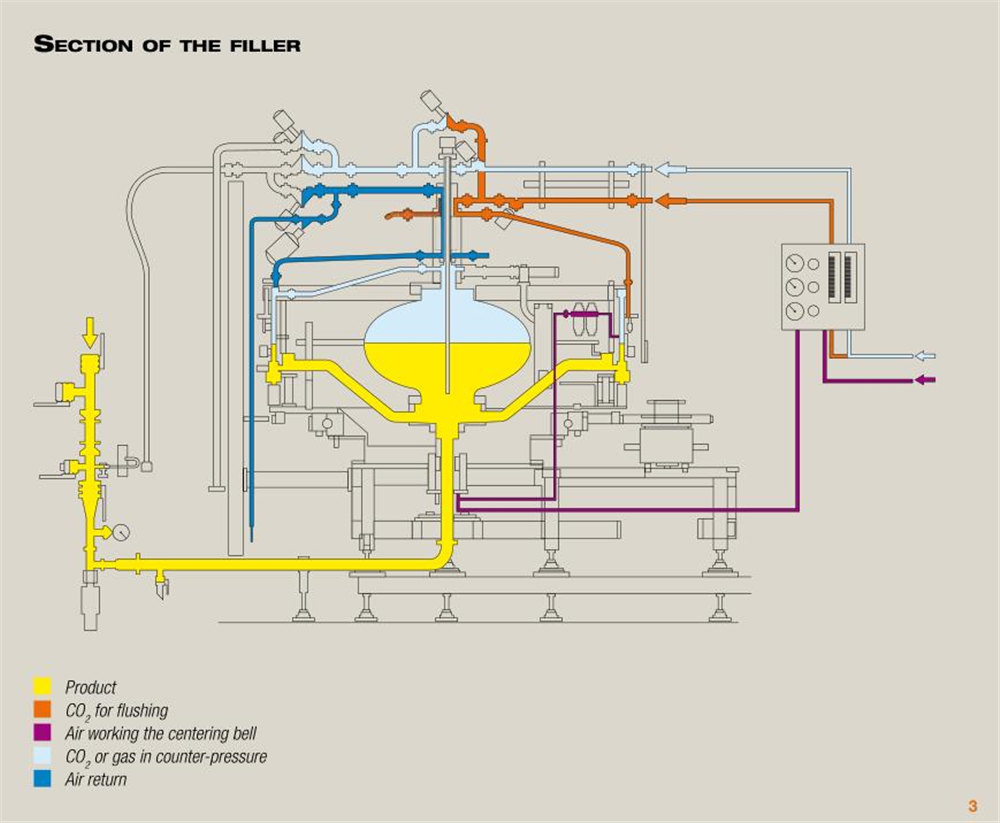

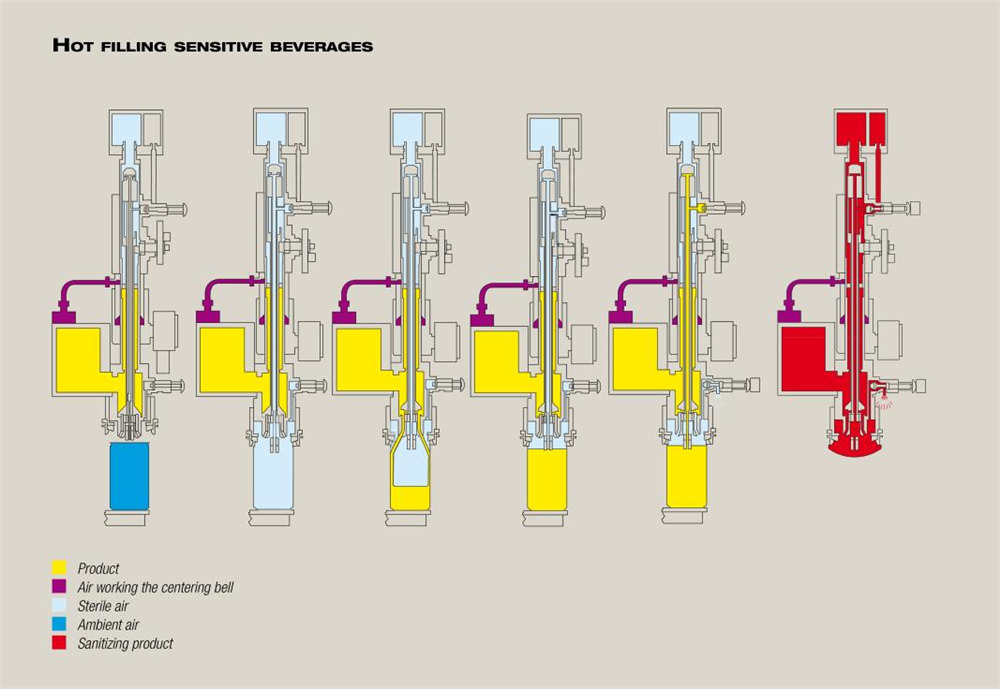

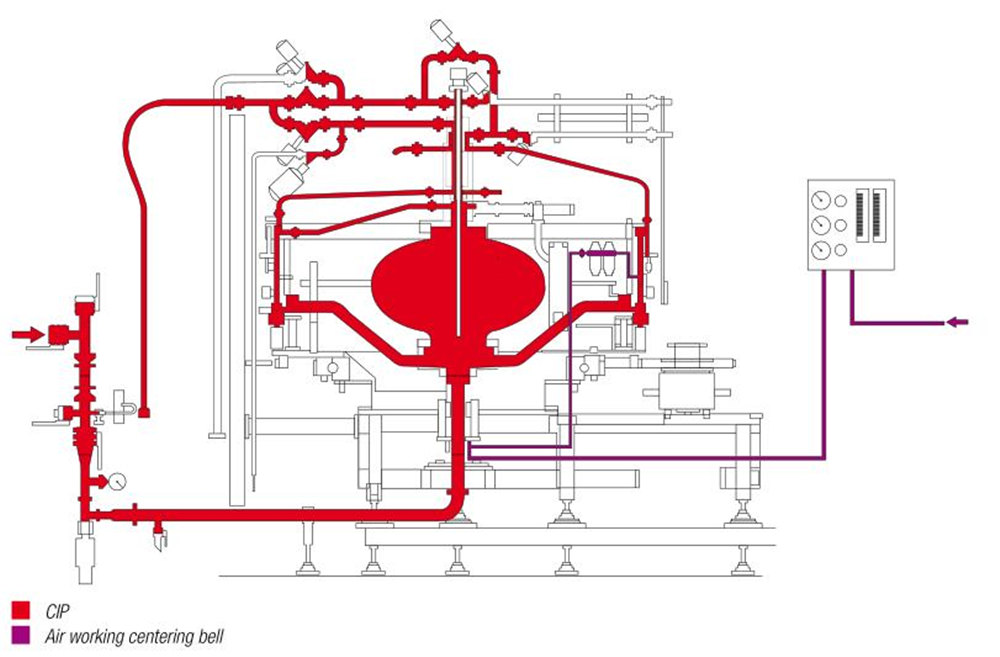

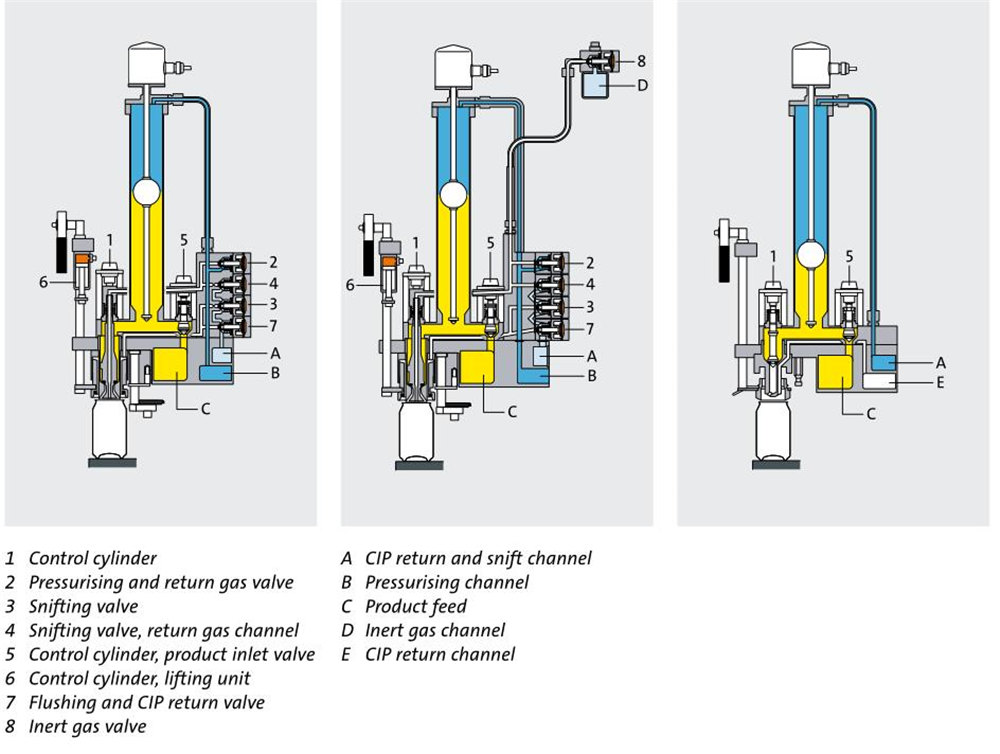

Umshini wokugcwalisa we-GEM-TEC uthuthukisiwe ngemikhiqizo ehlukahlukene engqondweni: ubhiya, iziphuzo ze-carbonated/soft, amajusi wezithelo, iziphuzo zezemidlalo namatiye ukubiza ezimbalwa.Kunesixazululo esifanelekile sokugcwalisa umkhiqizo ngamunye.Isibonelo, kumodi yokugcwalisa okushisayo edingwa yijusi netiye, ifakwe uhlelo lokubuyisela kabusha ukuze kuqinisekiswe ukuthi umkhiqizo unokushisa okuzinzile, ngisho nangesikhathi sokuphumula.Kubhiya, i-CSD edingwa indlela yokugcwalisa isobaric, ifakwe ukufuduka kwe-CO2, ukuhlanzwa kwe-CO2, ukucindezela, ukucindezelwa kwengcindezi kanye neminye imisebenzi;Ngendlela yokugcwalisa amanzi acebile nge-hydrogen, indlela yokugcwalisa yokugcwalisa phansi kanye ne-down-reflux ihlomele izici zobuningi obuphansi be-hydrogen nokuphunyuka kalula.Kungakhathaliseki ukuthi hlobo luni lwesiphuzo, iyiphi indlela yokugcwalisa, singakwazi ukwenza ngokwezifiso imboni ehamba phambili yokugcwalisa ubuchwepheshe kuwe.

1. I-valve yokugcwalisa evamile isebenzisa i-valve yokugcwalisa enokwethenjelwa, elula yemishini, ngokusho kokucushwa komkhiqizo ohlukile we-valve yokugcwalisa ehambisanayo.I-valve yokugcwalisa ene-elekthronikhi enesisindo esiphezulu noma i-electromagnetic flowmeter quantitative filling valve ikhethwa ngokuya ngohlobo lomkhiqizo.Isilinda se-valve ye-elekthronikhi ene-Teflon bellows yokulawula amagesi enqubo.Amanye ama-valve emishini nawo wonke ama-elekthronikhi anokulawulwa kwe-pneumatic yomkhono wesikhungo, ayikho i-CAM yokuphakamisa, inqubo yokugcwalisa ayidingi ukuphakamisa amathini.

2. Isistimu yokulawula ye-Siemens, enekhono eliphezulu lokulawula okuzenzakalelayo, zonke izingxenye zomsebenzi wokusebenza okuzenzakalelayo, akukho ukusebenza ngemva kokuqala (Isibonelo: isivinini sokugcwalisa silandela isivinini somugqa wonke, ukutholwa kwezinga le-liquid, ukulungiswa kokuphakelayo, uhlelo lokugcoba, njll.)

3. Ukudluliswa komshini kusebenzisa ukwakheka kwe-modular, ukuguqulwa kwemvamisa ukulawulwa kwesivinini esingenasinyathelo, ukulawulwa okubanzi kwejubane.Idrayivu ifakwe i-othomathikhi yomshini wokugcoba amafutha, ongahlinzeka ngamafutha endaweni ngayinye yokugcoba ngokwesidingo sesikhathi kanye nenani, ngokugcotshwa okwanele, ukusebenza kahle okuphezulu, umsindo ophansi nempilo ende yesevisi.Ingakwazi futhi ukusebenzisana nomshini wokuhlanganisa ukusebenzisa i-servo kagesi yokuhlukanisa idrayivu, akukho ukuhanjiswa kwemishini eyinkimbinkimbi engakwazi ukuhlala kalula umshini wokugcwalisa nokuvumelanisa umshini wokuhlanganisa, ukudluliselwa okuthembekile, ukugcinwa okulula.

4. Ukuphakama kwempahla kusilinda sokugcwalisa kutholwa yi-probe ye-elekthronikhi, futhi isilawuli se-PLC esivaliwe se-PID siqinisekisa izinga le-liquid elizinzile nokugcwalisa okuthembekile.

5. Isiteshi sezinto ezibonakalayo singahlanzwa i-CIP ngokuphelele, futhi ibhentshi lomsebenzi kanye nengxenye yokuxhumana yebhodlela ingagezwa ngokuqondile, ehlangabezana nezidingo zenhlanzeko zokugcwalisa;Ingasetshenziswa ngokuvumelana nesidingo setafula lokutsheka ohlangothini olulodwa;Izinkomishi mbumbulu ze-CIP ezizenzakalelayo nazo ziyatholakala.

6. Ifanele imikhiqizo ehlukahlukene kanye namamodeli omshini wokuvala uphawu.

Ukuze uqinisekise ukunambitheka okuhle kakhulu kanye nokusha kweziphuzo ezizogcwaliswa, kuyadingeka ukugoqa futhi uvale isivalo sethini ngokushesha ngemva kokugcwalisa.Umshini wethu wokuvala isivinini esikhulu othomathikhi usetshenziselwa ukuxhuma imishini yokugcwalisa ehlukahlukene ngemuva komugqa wokukhiqiza ukudla okusemathinini nesiphuzo.Umgomo wokusebenza ukuthi isihlalo sethangi esisekelayo esiphansi sishayela umzimba wethangi ukuthi ujikeleze futhi uphakamise, bese isondo lokuqala nelesibili lokuvala lisebenza emaphethelweni ekhanda eligoqekayo ngokulandelana, bese ngokusebenzisa i-CAM yokuvala ukuze uqedele isenzo sokuvala.Ingalungiselelwa ngamakhanda athandelayo angu-2/4/6/8, anamandla okubopha ngesivinini esiphezulu afika kumakani angu-700-800 ngomzuzu.Imodeli ngayinye ifakwe amadivayisi amaningi okuvikela ukuphepha ukuze kuqinisekiswe ukusebenza kwesibili kokubuyisela emuva ekusebenzeni kwesivinini esikhulu.Ukushintshwa kohlobo lwethangi kulula kakhulu futhi kuyashesha.

Izimpawu Zemishini

1. Isakhiwo se-modular sihlangene, sisontekile nazo zonke izingxenye zebheringi enokugcoba okuphakela uwoyela okuzenzakalelayo okuphakathi, okokugcoba kwamasondo okuvala ikhoyili okwakhelwe ngaphakathi.

2. Ilawulwa yi-converter frequency, isivinini sokukhiqiza singashintshwa ngokukhululekile;Ubuchwepheshe be-servo motor bungakhethwa ukuze kubonwe ukuhlukaniswa kanye nokudluliswa okuvumelanayo komshini wokugcwalisa kanye nomshini wokubopha ukuze kuncishiswe izingxenye zokuhambisa ngomshini.

3. Isihlalo se-coil sealing roller kulula ukusilungisa, i-coil sealing roller kusetshenziswa ukwelashwa kwe-titanium nitride (TIN) ngaphezulu.

4. Umshini ojwayelekile wokunqanda ikhava yethangi (i-clamp cap), inganciphisa ingcindezi yokunqwabelana kwekhava yethangi lokuphakelayo.

5. Umshini ufakwe izinto eziningi zokuphepha ezixhumene ukuze kuqinisekiswe ukuphepha komshini womuntu.

6. Indawo yokuxhumana phakathi kwesondo lenkanyezi yokudlulisa kanye nomzimba wethangi iphathwa nge-chromium plating ukuvimbela umzimba wethangi ukuthi ungaklwebheki.

7. Ukulawula i-HMI(isikrini sokuthinta), kungaba isimo somshini ngokoqobo, uhlobo lokwehluleka kanye nolwazi oluphelele lokukhiqiza.

8. Isihlangu sangaphandle sensimbi engagqwali kanye newindi lengilazi eliqinile.

9. Idizayini ephelele yokuhlanzeka, kulula ukuyihlanza.

10. (Ongakukhetha) Umshini wokuphakamisa ikhoyili kagesi.

11. (Ongakukhetha) CO2 kanye nedivayisi yokuhlanza umhwamuko ngaphansi kwekhava yethangi.

Ipharamitha

| Ipharamitha yobuchwepheshe:isiphuzo sesiphuzo singagcwalisa imishini | |||||

| Imodeli | JH-CF12-1 | JH-CF18-4 | JH-CF24-4 | JH-CF30-6 | JH-CF40-8 |

| Amandla (amathini/ihora) | 2000 | 8000 | 12000 | 15000 | 20000 |

| Isitsha esifanelekayo | I-Aluminium Can / Tin Can / Plastic Can | ||||

| Can idayamitha | Dia50 ~ dia99mm | ||||

| Ingakwazi ukuphakama (mm) | 70-133 mm | ||||

| Umoya we-compressor | Ukugcwaliswa kwe-Isobaric / ukugcwaliswa kwengcindezi evamile | ||||

| Isicelo | Umshini Wokugcwalisa Isiphuzo | ||||

| Amandla aphelele (kw) | 2.4kw | 4.4kw | 5.2kw | 6.2kw | 7.2kw |

| Izilinganiso sezizonke | 2.5*1.9m | 2.8*1.9m | 3.2*2.15m | 3.5*2.5m | 3.8*2.8m |

| Ubude | 2.3m | 2.5m | 2.5m | 2.5m | 2.5m |

| Isisindo(kg) | 2500kg | 3200kg | 4000kg | 4500kg | 6500kg |

Isakhiwo