Ibhodlela Lengilazi Elizenzakalelayo/ Ibhodlela Lepulasitiki/ Ingakwazi Ukugcwalisa Umshini Wejusi Oshisayo

Incazelo

Ngenkathi uzama ukudala iziphuzo ezihlukile, ezicolisisiwe zamakhasimende akho, okokusebenza kwakho kwamabhodlela kufanele kugcine izinga elifanayo lokunemba kanye nobuciko.Umshini wokugcwalisa uchungechunge lwe-JH-HF uyisinqumo esingcono kakhulu se-PET & ingilazi yebhodlela lengilazi yokugcwalisa umusi imikhiqizo yamahhala.Ingasetshenziselwa ukugcwalisa ijusi, umpe, iziphuzo ezibandayo, itiye nezinye iziphuzo.Ukuthengiswa kwalezi ziphuzo kukhula ngokushesha, futhi zimele indlela yokuphila enempilo eqhutshwa ukufudukela emadolobheni kanye nengqalasizinda ethuthukisiwe yokudayisa.Kungakhathaliseki ukuthi uluphi uhlobo lwesiphuzo, singakusiza ukupakisha amaphupho akho ngochwepheshe bethu bobuchwepheshe namandla okupakisha aphakeme.

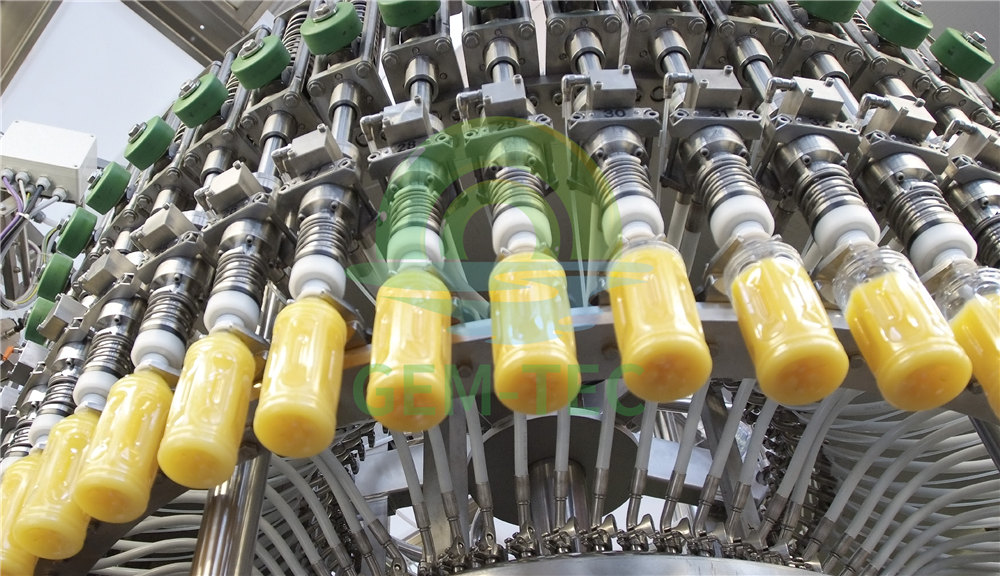

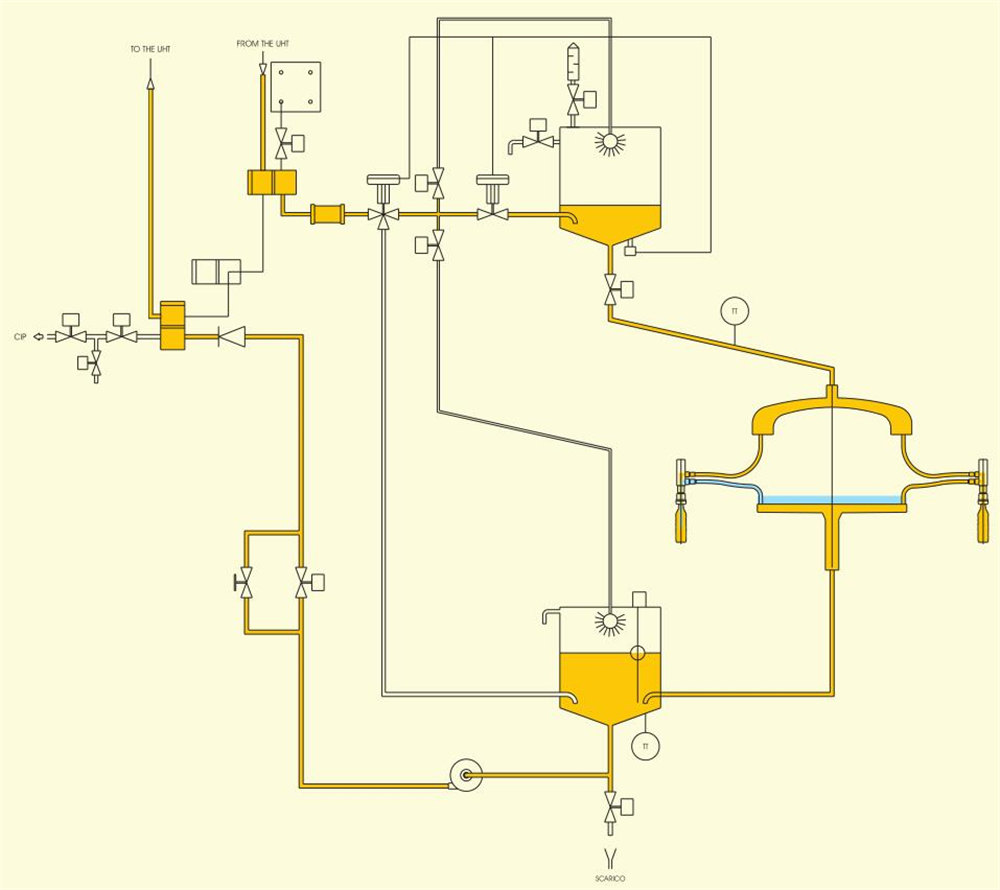

Ubuchwepheshe bokugcwalisa okushisayo bumele isisombululo sokugcwalisa iziphuzo ezimile ngaphandle kokwengezwa kwezilondolozi ezifana ne-pulp yesithelo noma i-fiber.Imikhiqizo eshisayo emazingeni okushisa aphezulu (kufika ku-92-95 ° C, kuye ngokucaciswa komkhiqizo) igcinwa ekushiseni okuphezulu kanye nesimo esifakwe inzalo kusuka ku-pasteurizer kuya emshinini wokugcwalisa ukuze kuqinisekiswe impilo yeshalofu oyifunayo.Uhlelo lokugcwalisa okushisayo lufakwe umsebenzi wokubuyisela kabusha ukuze kuqinisekiswe ukuthi umkhiqizo awunanyumba ngaso sonke isikhathi.Lapho umshini uyeka ukusebenza, ukuqala kabusha komkhiqizo, kugcina izinga lokushisa le-valve yokugcwalisa lingashintshi.Ukuphindaphinda kwenzelwe kuphela imikhiqizo etholakala ku-valve yokugcwalisa, hhayi yemikhiqizo yamabhodlela.Ngesikhathi sokugcwalisa, i-valve yokugcwalisa ihamba ngokuthinta ibhodlela.Ibhodlela elixhumene ne-valve livula i-valve ngaphandle kokubuyisela kabusha umkhiqizo.Umoya ophuma ebhodleleni ukhishwa ngeshubhu lokubuyisela kabusha umkhiqizo.Uma izinga lokugcwalisa selifinyelelwe, ukuphindaphinda komkhiqizo kuqala futhi.Khona-ke i-valve ye-pneumatic ivala ikhanda lokugcwalisa futhi imise ukuphindaphinda komkhiqizo.Uma seligcwalisiwe futhi limboziwe, ibhodlela lingena emhubheni weshawa ebandayo ukuze lipholiswe.

Ukuze kwandiswe ukuvikeleka komkhiqizo ekungcolisweni kwebhaktheriya kanye nokwandisa ukusebenza kahle kokuhlanza kwemishini, umkhiqizo usatshalaliswa ngepayipi kumshini ojikelezayo.Ukuphela okuphezulu komsabalalisi kuxhunywe nethangi lokugcina impahla, ithangi lokugcina lingamukela izinto ezivela emshinini wokuvala inzalo futhi lingabuyisela izinto ezijikelezayo ku-valve yokugcwalisa emshinini wokuvala inzalo ukuze uqhubeke nokuvala inzalo.Ingxenye yethangi ihlanzwa ngebhola le-spray.Ukulethwa nokubuyiselwa komkhiqizo ngaphakathi kwe-valve yokugcwalisa kubuye kuklanyelwe ukunciphisa ukulahlekelwa komkhiqizo ekuqaleni nasekupheleni kokukhiqiza.Le valve yokugcwalisa ekhethekile ayidingi ukufakwa kwendebe yamanga yokuhlanza i-CIP ngoba kukhona i-loop evaliwe ngaphakathi kwe-valve evumela ukuthi ukuhlanza kwenziwe.Ukuma kwendawo yokuxhumana phakathi kwezingxenye ezilungisiwe nezihambayo kuklanyelwe ukunikeza izinga lokugeleza elifanele lokuhlanza.

Izici

Izici zobuchwepheshe bokugcwalisa okushisayo

1. Izinto ezisetshenziswayo zinethangi langaphandle lokuphakela kanye nokugaywa kabusha kwemikhiqizo.Uma umshini ungenawo amabhodlela, umkhiqizo uvuselelwa kabusha: ikhanda lokugcwalisa lihlala ligcinwe ekushiseni okuphezulu.

2. Isistimu yokulawula ye-Siemens, enekhono eliphezulu lokulawula okuzenzakalelayo, zonke izingxenye zomsebenzi wokusebenza okuzenzakalelayo, akukho ukusebenza ngemva kokuqala.

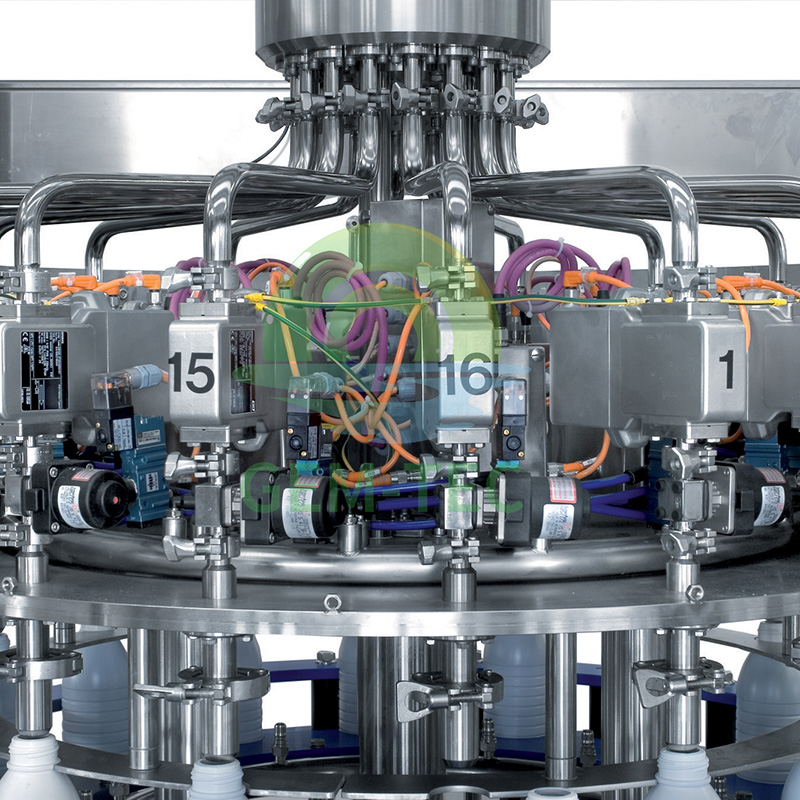

3. Ukulawula i-electronic kanye ne-pneumatic yawo wonke ama-valve okugcwalisa, ukugcinwa okulula.Ukugcwaliswa okunembe okunembe ongakukhetha, uhlobo lokungeniswa kwe-electromagnetic flowmeter volumetric filling, i-valve yokugcwalisa nebhodlela ungaxhumani ngesikhathi senqubo yokugcwalisa, gwema ukungcoliswa okuphambanayo.

4. Isiteshi sezinto ezibonakalayo singahlanzwa i-CIP ngokuphelele, futhi ibhentshi lomsebenzi kanye nengxenye yokuxhumana yebhodlela ingagezwa ngokuqondile, ehlangabezana nezidingo zenhlanzeko zokugcwalisa;Izinkomishi mbumbulu ze-CIP ezizenzakalelayo nazo ziyatholakala.

5. Ukuqinisekisa izinga eliphezulu lokuhlanzeka esinyathelweni ngasinye, umshini wakhiwe ngensimbi engagqwali futhi une-countertop eyehlelayo ukuze unciphise ingozi yokungcoliswa kwamagciwane.

6. Ukulawulwa okuthuthukisiwe kokujikeleza kabusha nge-actuator yangaphandle kunguqulo ye-pneumatic ye-membrane valve ukulawula izinga lokuphindaphinda komkhiqizo futhi kugwenywe isiphalaphala somkhiqizo.

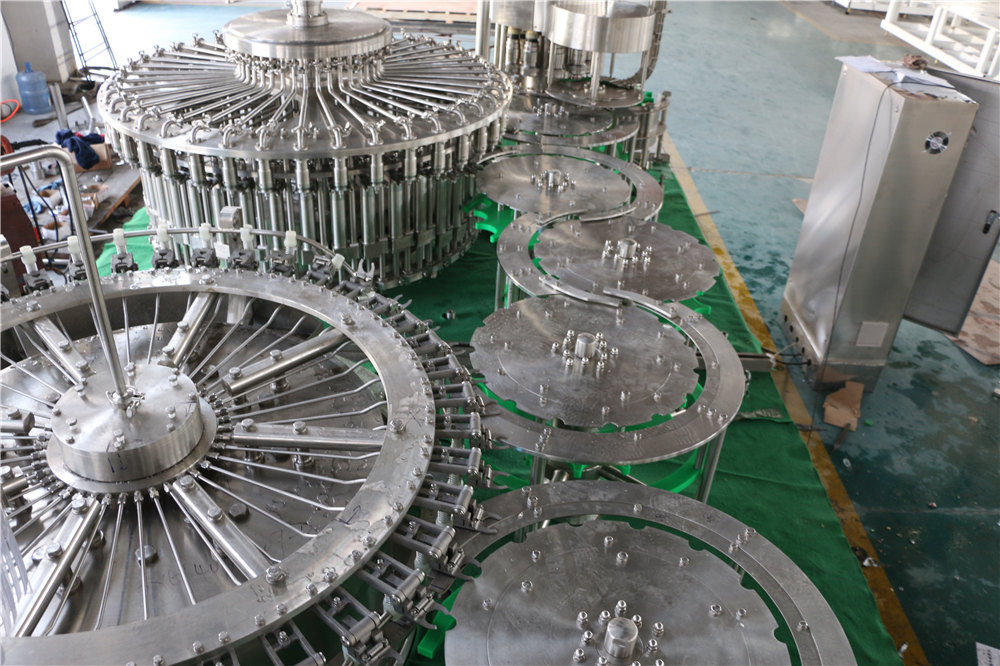

7. Ukudluliswa komshini kwamukela ukuklama kwe-modular, ukuguqulwa kwemvamisa ukulawulwa kwesivinini esingenasinyathelo, ububanzi obubanzi bokulawulwa kwejubane.Idrayivu ifakwe i-othomathikhi yomshini wokugcoba amafutha, ongahlinzeka ngamafutha endaweni ngayinye yokugcoba ngokwesidingo sesikhathi kanye nenani, ngokugcotshwa okwanele, ukusebenza kahle okuphezulu, umsindo ophansi nempilo ende yesevisi.

8. Izinguqulo ezahlukene zinganikezwa ngokusho kwemininingwane yamakhasimende.

Isakhiwo

Ukucaciswa Kwezobuchwepheshe

Ingxenye Yemikhiqizo Eyinhloko Ipharamitha Yobuchwepheshe

| Imodeli | Ukugeza amakhanda | Ukugcwalisa amakhanda | I-Capping amakhanda | Ukukhiqiza Amandla | Umshini Amandla | Isisindo | Ubukhulu bebonke (mm) |

| JG-HF 14-12-4 | 14 | 12 | 5 | 4000B/H (500ml) | 3kw | 3200kg | 2500*1880*2300mm |

| JG-HF 18-18-6 | 18 | 18 | 6 | 8000B/H (500ml) | 3kw | 4500kg | 2800*2150*2300mm |

| JG-HF 24-24-8 | 24 | 24 | 8 | 8000B/H (500ml) | 5 kw | 6500kg | 3100*2450*2300mm |

| JG-HF 32-32-10 | 32 | 32 | 10 | 15000B/H (500ml) | 6kw | 7500kg | 3680*2800*2500mm |

| JG-HF 50-50-12 | 50 | 50 | 12 | 20000B/H (500ml) | 11kw | 13000kg | 5200*3700*2900 mm |