Umshini Wokugcwalisa Utshwala Webhodlela Lengilazi/ Umshini Wokugcwalisa Utshwala WeWhisky

Incazelo

Imimoya iziphuzo ezidakayo ezigaywe ngaphandle kokuvutshelwa.Imimoya e-distilled ivame ukuba nephesenti eliphezulu lesilinganiso sotshwala ngevolumu, kusukela ku-20% kuya ku-90% ABV.Ukwenza umoya onamandla, izinto zokusetshenziswa ezifana nezithelo, amazambane kanye nokusanhlamvu zisetshenziselwa inqubo ye-distillation.Iziphuzo ezidakayo ezincibilikisiwe ezijwayelekile yi-whisky, i-gin ne-vodka.Imakethe yesiphuzo esidakayo emhlabeni wonke kulindeleke ukuthi ifinyelele cishe ku- $ 2 trillion ngo-2025, kusho ucwaningo.Imimoya izolandisa cishe ingxenye yesithathu yemakethe isiyonke.Okubonakalayo, imimoya yenza ingxenye enkulu yemakethe.

Uma inani lomkhiqizo liphakeme, ukulahlekelwa okuningi kuzovela ekulinganisweni kokugcwalisa okungalungile.Ukuze ugweme ukulahlekelwa okunjalo, umshini wokugcwalisa utshwala we-GEM-TEC ulandela ngokuqinile izidingo zenqubo yokugcwalisa okunembile.Uma umkhiqizo omningi uthululelwa esitsheni, isistimu izolungisa ngokuzenzakalelayo izinga le-liquid.Imikhiqizo enotshwala obuphezulu nayo idinga ukwelashwa okungaqhumeki ekufakeni amabhodlela.Isistimu kagesi yomshini wethu isebenzisa imikhiqizo engaqhumi ukuze isuse izingozi zokuphepha ezingaba khona.Izixazululo zethu kulula ukuzihlanza ukuze imikhiqizo yakho ikwazi ukuhlangabezana nazo zonke izidingo zenhlanzeko.

Isimiso sokusebenza sokugcwalisa utshwala obucacile esitsheni seglasi

Umshini wokugcwalisa imimoya ngokuvamile usebenzisa indlela yokugcwalisa i-vacuum.Imimoya ejovwe ebhodleleni ihlakazwa odongeni lwangaphakathi lwebhodlela ngesambulela esiphambukisayo, futhi umoya osebhodleleni udonswa yi-vacuum system ngepayipi elibuyayo.Inqubo ethize imi kanje: ibhodlela liphakanyiswa kuze kube phansi kwe-valve yokugcwalisa futhi i-valve yokugcwalisa ivuliwe.Ukugcwaliswa kuyaqala.Lapho izinga le-liquid lewayini ebhodleleni liphakeme kunepayipi lokubuyisela, i-valve izovalwa.Izinga le-liquid libe selilungiswa nge-vacuum: umkhiqizo oweqile umuncwa emuva kusilinda sokugcwalisa ngeshubhu elifushane.Ngoba umsebenzi wokuvula nokuvala we-valve ulawulwa ibhodlela, ngakho-ke: "akukho bhodlela, akukho nqubo yokugcwalisa".

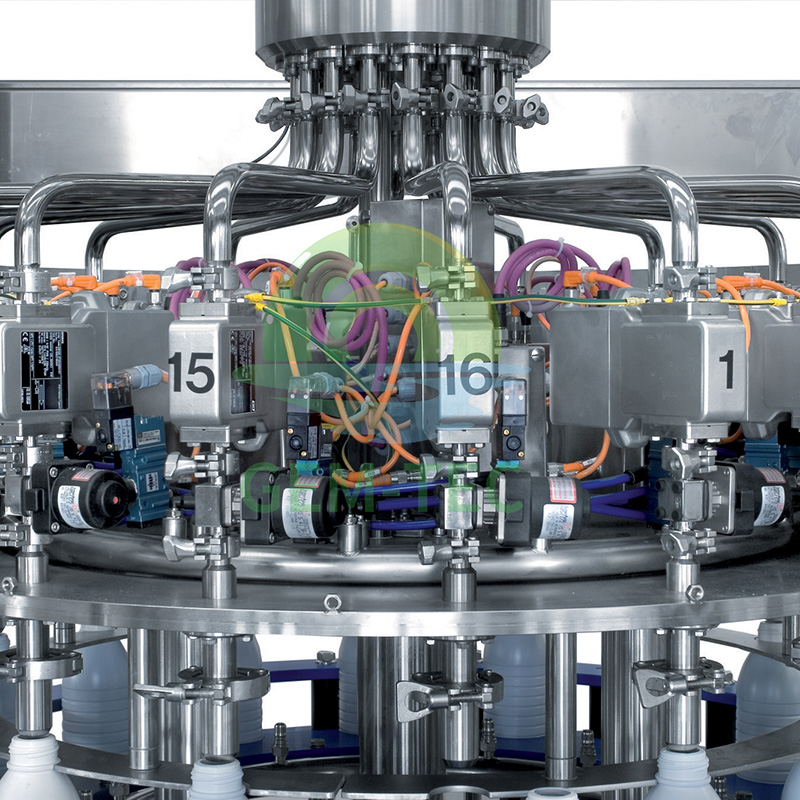

Vele, ekugcwalisweni kotshwala kwe-GEM-TEC kungasebenzisa futhi uhlelo lokugcwalisa inani lebhola elintantayo le-elekthronikhi, ukunemba kokugcwalisa kuphezulu, kuyashesha.I-valve ye-elekthronikhi ithatha ubuchwepheshe bokulinganisa nokulawula isikhathi sangempela, ubuchwepheshe bokunxeshezelwa kokusebenza kokulandela i-PLC kanye nobuchwepheshe bokulawula ukugeleza okuguquguqukayo ukuze kuqhutshekwe nokunemba kokugcwalisa kanye nesivinini sokugcwalisa ekuphakameni okusha.Inqubo yokugcwalisa iphinde ifane nesakhiwo se-valve yezindlela ezintathu.Imimoya ifakwa kuqala emgqonyeni we-electronic metering.Ngemva kokufinyelela umthamo obekiwe, imimoya emgqonyeni wemitha isuke ijovwe ebhodleleni.

Izici

Izici zokusebenza kwe-valve yemishini

1. Qinisekisa amazinga afanele okugcwalisa amaphutha kanye nokulahleka kotshwala

2. Thola ngokunembile ubude bezinga lokugcwalisa ngokulungiswa kwe-vacuum kanye nobude bepayipi lokubuyisela

3. I-valve yokugcwalisa elawulwa ngomshini, ingaba +/- 4 mm ubude bokugcwalisa obungenasinyathelo

4. I-valve yokugcwalisa ngokuzithandela enomsebenzi we-CIP noma ngaphandle kwayo

5. Isitsha sokugcina sisesimweni esiphansi se-vacuum, ngaphandle kokugcwalisa i-drip

6. Isistimu yokulawula ye-Siemens, enekhono eliphezulu lokulawula okuzenzakalelayo, zonke izingxenye zomsebenzi wokusebenza okuzenzakalelayo, akukho ukusebenza ngemva kokuqaliswa

7. Ukudluliswa komshini kusebenzisa ukwakheka kwe-modular, ukulawulwa kwesivinini esiguquguqukayo esingenasinyathelo, ububanzi besivinini.Idrayivu ifakwe i-othomathikhi yomshini wokugcoba amafutha, ongahlinzeka ngamafutha endaweni ngayinye yokugcoba ngokwesidingo sesikhathi kanye nenani, ngokugcotshwa okwanele, ukusebenza kahle okuphezulu, umsindo ophansi nempilo ende yesevisi.

8. Ukuphakama kwempahla kusilinda sokugcwalisa kutholwa yi-electronic probe.Ukulawulwa kwe-PID ye-PLC evaliwe kuqinisekisa izinga loketshezi elizinzile nokugcwalisa okuthembekile.

9. Izindlela zokuvala ezihlukene ziyakhethwa (njengalezi: ikepisi le-aluminium, ikepisi lomqhele, indlala emise okwehlukene, njll.)

10. Isiteshi sezinto ezibonakalayo singahlanzwa i-CIP ngokuphelele, futhi ibhentshi lomsebenzi kanye nengxenye yokuxhumana yebhodlela ingagezwa ngokuqondile, ehlangabezana nezidingo zenhlanzeko zokugcwalisa;Ingasetshenziswa ngokuvumelana nesidingo setafula lokutsheka ohlangothini olulodwa;Izinkomishi mbumbulu ze-CIP ezizenzakalelayo nazo ziyatholakala.

Ngaphezu kwalezi zici ezingenhla, i-valve ye-elekthronikhi nayo inezici ezilandelayo:

● Akukho ukulahlekelwa, kulula ukulungisa: ibhodlela kwinqubo yokugcwalisa ngaphandle kokuphakamisa ukunyakaza, alithinti umzimba we-valve, cishe akukho izingxenye zokugqoka;Lapho ulungisa umthamo, udinga kuphela ukuthinta isikrini esithintwayo ukuze uguqule imingcele ukuze wenze ukulungisa okungenasinyathelo, futhi ungagcina nemingcele yezinhlobonhlobo zewayini ohlelweni lwefomula.Lapho ushintsha iwayini, udinga kuphela ukubiza okuhlukahlukene esikrinini sokuthinta ukuze ugcwalise ngokuzenzakalelayo, uthuthukise kakhulu ukusebenza kahle kokukhiqiza.

● Ukucushwa okuphezulu, ukuthembeka okuphezulu: uma kuqhathaniswa nesistimu ye-valve engumshini, izingxenye eziningi ze-elekthronikhi zibamba iqhaza enqubweni yokugcwalisa, ukulawulwa kwesistimu kunembe kakhulu, ukutholwa okubucayi kakhulu.

● Alukho uketshezi oluklinywayo, alukho ukuconsa: i-valve yokugcwalisa ithatha isiteshi sokudambisa, utshwala akulula ukuchichima ukuchichima, eduze nomlomo webhodlela lapho izinga lokugeleza koketshezi lehla, ikholomu ye-liquid iba ngcono futhi ifakwe kancane kancane ebhodleleni, isuse uketshezi. igwebu, ukubekwa uphawu okuphambene ngemva kokugcwalisa, akukho ukuconsa.

Ipharamitha Yezobuchwepheshe

| Uhlobo lomshini | ikhanda lokugcwalisa | Ukuphakama kwebhodlela | Ububanzi bebhodlela | Ukusebenza kahle kokukhiqiza | Ukugcwalisa ukunemba | Ububanzi bokugcwalisa | Umfutho womoya ocindezelwe |

| JH-FF18 | 18 | 100-300 | 50-100 | ≤6600(b/h) | ±1.0ml/500ml | 40-600 ml | 0.4-0.5MPa |

| JH-FF 24 | 24 | 100-300 | 50-100 | ≤9000(b/h) | ±1.0ml/500ml | 40-600 ml | 0.4-0.5MPa |

| JH-FF 36 | 36 | 100-300 | 50-100 | ≤14000(b/h) | ±1.0ml/500ml | 40-600 ml | 0.4-0.5MPa |

| JH-FF 48 | 48 | 100-300 | 50-100 | ≤18000(b/h) | ±1.0ml/500ml | 40-600 ml | 0.4-0.5MPa |

| JH-FF 60 | 60 | 100-300 | 50-100 | ≤22000(b/h) | ±1.0ml/500ml | 40-600 ml | 0.4-0.5MPa |

| JH-FF 72 | 72 | 100-300 | 50-100 | ≤26000(b/h) | ±1.0ml/500ml | 40-600 ml | 0.4-0.5MPa |