I-Automatic Robot Carton Box / Shrink Wrapping Palletizer

Ividiyo

Incazelo

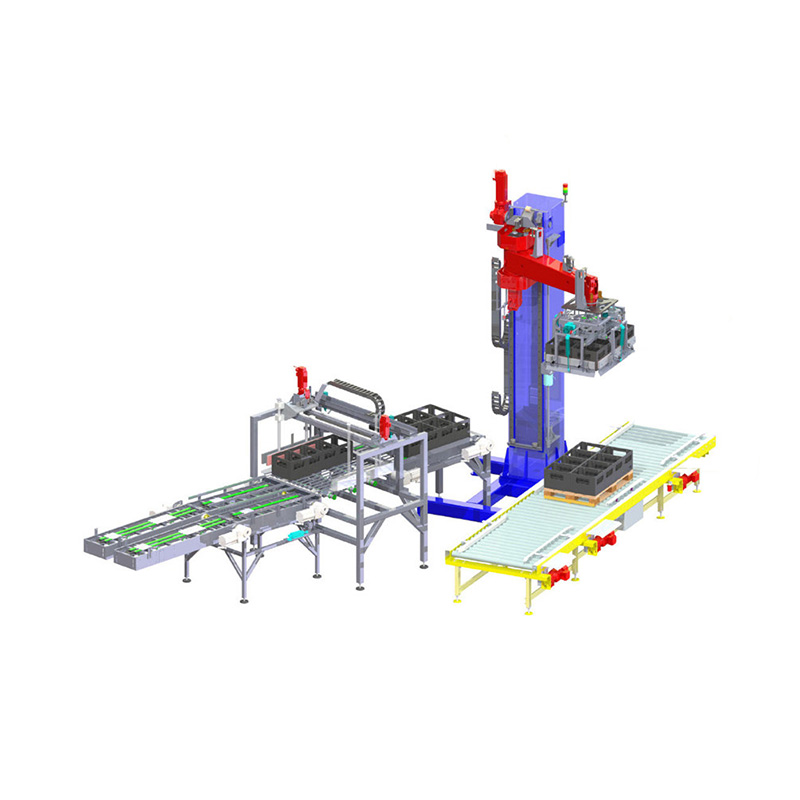

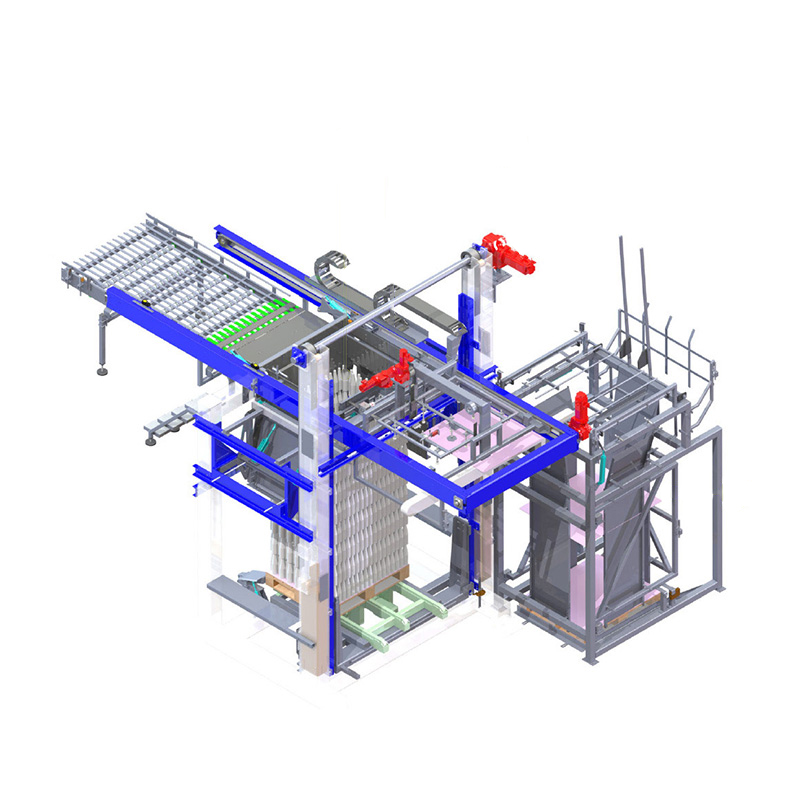

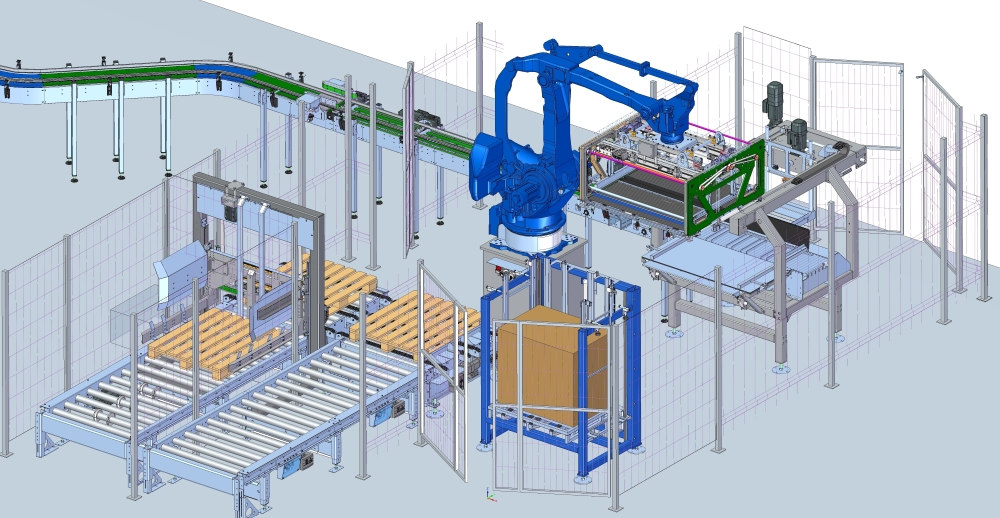

I-Robot palletizer ingumkhiqizo olayishwe ebhokisini, ibhokisi lemali, izikhwama kanye neminye imithetho yomkhiqizo, ngomugqa wokuthutha uzohlelwa futhi ubekwe;Amaphalethi angu-10-12 abekwe kahle abekwe emshinini we-pallet othomathikhi nge-forklift, futhi umshini uhlukanisa ngokuzenzakalelayo ama-pallets ngokulandelana futhi uwathumele endaweni yokuphalethwa ukuze abekwe futhi ahlanganiswe.Irobhothi lizobamba umkhiqizo ngomshini okhethekile, futhi ngokuhambisana nokubekwa kwangaphambili okusethiwe kuphalethi, umugqa wokuthutha wephalethi uqala ngemva kokuqedwa kwemishini yokukhipha i-palletizing pallet, ngemfoloko yokukhipha umugqa.Yonke le nqubo iqedwa ngokuzenzakalelayo ngaphandle kokungenelela komuntu.Ifanele ukusetshenziswa komugqa wokuhlanganisa, inganciphisa kakhulu abasebenzi futhi inciphise umfutho wabasebenzi.Yamukela umqondo wesivinini esikhulu, idizayini eqinile neyonga isikhala, ukulondoloza isikhala ngokushesha nangokwengeziwe.Umshini owodwa onezinjongo eziningi, ukulungisa okusheshayo, akudingeki ukuthi umiselele imikhiqizo estakiwe nokukhathazeka.

Ububanzi bokufaka isicelo: ibhokisi likathayela, ibhokisi lepulasitiki, ukupakishwa kwamabhakede, ukupakishwa kwezikhwama, njll.

Ukubunjwa kwezisetshenziswa: umugqa wokudlulisa umkhiqizo, umugqa wokumisa, irobhothi le-palletizing, isisekelo, isilungiselelo, umshini wokusabalalisa i-pallet, umugqa wokudlulisa i-pallet, uhlelo lokulawula ugesi kanye nenetha lokuvikela ukuphepha, njll.

Izici

1. Ukusetshenziswa kwamarobhothi e-ABB noma e-KUKA noma e-yaskawa, ukuze kuqinisekiswe ukuthi indawo yokupakisha inembile futhi izinzile.

2. Kungenziwa kusengaphambili izinqubo ezihlukahlukene ze-palletizing, ukucaciswa koshintsho kungabizwa nganoma yisiphi isikhathi esikrinini sokuthinta, ngaphandle kokufaka izingxenye.

3. Ukusetshenziswa okuguquguqukayo, irobhothi lingahambisana nokucaciswa okuhlukile kwe-1-4 kwemikhiqizo ngesikhathi esifanayo i-palletizing, ukuhambisana okuqinile.

4. Umthamo welabhulali ye-pallet mkhulu, ungamukela i-pallet engenalutho engu-10-12, ingakwazi ukubona ukunikezwa okuzenzakalelayo kwe-pallet.

5. Ukusetshenziswa kwezingxenye zikagesi zohlobo lokuqala lwamazwe ngamazwe, ukuze kunqunywe ukuqina kwempahla.

6. Ihlanzekile, inhle futhi isebenza kahle;Kunganciphisa kakhulu ukusebenza.

7. Ukusebenza kwesikrini sokuthinta ukuze kuzuzwe inkhulumomphendvulwano yomshini womuntu, kungabonisa isivinini sokukhiqiza, imbangela yephutha nendawo, izinga eliphezulu lokuzenzakalela.

8. I-PLC ingahlelwa ukuthi ilawule inani lezendlalelo zokupakisha, ukunikezwa kwe-pallet kanye nokukhishwa kwamabhokisi.

9. Uhlelo lokulawula: isilawuli sesikrini sokuthinta, nge-manual, imodi yokusebenza okuzenzakalelayo, isikrini sokuthinta nawo wonke umsebenzi wokusebenza komshini.

10. Ukuqapha ngesikhathi sangempela yonke inqubo yokusebenza kwemishini.Zonke izinyathelo zokusebenza zitholwa yizinzwa ezinomsebenzi wokuzixilonga.Uma kwenzeka noma yiliphi iphutha, okokusebenza kuzoma ngokuzenzakalela, isibani se-alamu sizokhanya, futhi uhlobo lwephutha luzovezwa esikrinini sokusebenza.

11. Ikhabhinethi yokulawula kagesi ezimele, ibhokisi lokulawula eline-fan yokupholisa, isokhethi le-fluorescent.

12. Wonke umugqa uhlinzekwa nge-slot yocingo, futhi i-outlet slot ivikelwe nge-hose.

13. Amakhebuli amakwe ngezinombolo zolayini, kanti amatheminali acishiwe.

14. Okokusebenza okwenza ukunyakaza okuhambisanayo kwekhebula kusetshenziswa irobhothi ikhebula eliguquguqukayo elikhethekile.

Wonke umshini ufakwe umnyango wokuphepha, lapho umnyango uvuliwe, umshini uyayeka ukusebenza ukuze uqinisekise ukuphepha kwabasebenzi.

Ipharamitha Yezobuchwepheshe

| Uhlobo | I-XYMD-12/R |

| Umthombo wamandla | 380V 50HZ 20Kw |

| Umkhiqizo osebenzayo | Amakhathoni, amabhokisi okwenza inzuzo, izikhwama, imikhiqizo enemigqomo, njll |

| Ubukhulu bomkhiqizo | Yenza ngokwezifiso njengoba kudingeka |

| Usayizi wephalethi osebenzayo | L1000~1200*W1000~1200*H120~150mm(Ngokuvumelana nomklamo wangempela wephalethi) |

| Imodi yokuhlela | Yenza ngokwezifiso njengoba kudingeka |

| Ubude bokunqwabelanisa | ≤1800mm (Ukukhetha irobhothi kungenziwa ngokuya ngezidingo) |

| Isivinini | 10-12 beats ngomzuzu (Ngokokubekwa kohlobo lwesitaki kungaba ngaphezu kokubamba) |

| Umfutho womoya | ≥6 Kg/cm² |

| Ukusetshenziswa kwegesi | 0.2m³/min |

| Ukuphakama kwezokuthutha komkhiqizo | 900mm (Yenza ngokwezifiso njengoba kudingeka) |

| Iphalethi elidlulisa ukuphakama | 600mm (Yenza ngokwezifiso njengoba kudingeka) |

| Imodi yokuthutha yephalethi | Ngokusho kwesakhiwo se-pallet singasetshenziswa uhlobo lwesigubhu, uhlobo lwamaketanga, ipuleti leketanga, njll |

| Ukwakhiwa komshini | Ngokuvumelana nesakhiwo sangempela |

| Isisindo somshini | 2000Kg |

| Impahla yesisetshenziswa | Impahla eyinhloko yi-carbon steel yokufafaza ipulasitiki, futhi ingxenye ethintana nayo insimbi engagqwali (Yenza ngokwezifiso njengoba kudingeka) |

| Ukucushwa kwedivayisi | (Yenza ngokwezifiso njengoba kudingeka) |